Top Stories

Crane

Raimondi Cranes: the new T187 tower crane

Raimondi Cranes with the launch of the T187 inaugurates a truly unprecedented range of tower cranes featuring performance and modularity Raimondi Cranes has renewed the range of topless tower cranes, in particular the T187 model. This new crane represents a big step forward for the manufacturer as it inaugurates a new range construction process which represents the basis for the entire Class 110 series. One of the major changes implemented by Raimondi is a new design and development approach right in the production system of its tower cranes. The modularity of the mechanical and carpentry parts combined with the interchangeable elements has facilitated the mass production of a new family of eight cranes, designed on the basis of the most recent lean manufacturing techniques. Additional benefits are the ability to deliver higher quality standards and minimize site downtime while also reducing maintenance costs and spare parts inventory for rental companies. A perfect equipment for rental With all improvements in range, speed and headroom, the T187, like the entire Class 110, has been designed with and for rental companies. The variety of choices, 8 and 10 tonnes, II/IV pulling or permanent two lines, allows renters to meet clients’ needs and face different projects. Boom length of 67.5m and tip capacity of 1.61 tonnes in UltraLift allow the T187 to fit into premium lift systems. The T187 is therefore suitable for the construction of medium-high buildings, thanks also to the maximum lifting speed of 115 meters per minute (in the version with 37 kW hoist) and the drum capacity of 620 m. All the new winches are also equipped with the Down Over Speed (DOS) system which allows a substantial increase in intermediate speeds when descending. Maximum equipment management Each machine is now equipped with a central processing unit that guarantees operation even in extreme environmental conditions. Raimondi's new ConCore control system, thanks to electronic sensors and redundant controls, allows faster setup, extremely precise calibrations as well as targeted identification of any problem. The first in Belgium Raimondi has already provided an example of the T187 tower crane to ABHR, a Belgian construction company. The T187 was chosen for its best-in-class characteristics in terms of lift capacity and speed, also thanks to the new ConCore control system. The technical installation process included the first phase of preparation of the jib, counter-jib and slewing unit with cabin which took place on the ground, followed by the assembly of the 4.5 m HEB700 base, the assembly of the 1.5 m series mast elements and the final assembly at height of the pre-assembled muzzle elements on the ground. All supported by the use of a 200-ton mobile crane. “We are thrilled to be the first European construction company getting a machine from the new Raimondi series. We considered the lifting capacity and speed, as well as the weight-optimized components, which enable our installation procedures, as the most important characteristics in choosing this model,” said Max Van Gompel, General Manager of ABHR.

-

Rental

Is earthmoving equipment rental still attractive in 2023?

The profitability of the rental service in the construction sector in 2023 is directly involved with the ability of renters to change into advanced service providers Is leasing in the earthmoving machinery sector and construction in general worthwhile in 2023? The answer to this question is not simple and should be well analyzed starting from the Italian building peculiarity. The basis is that the rental business in the earthmoving machinery sector by 2023 must consider the current challenges in the environment and the mechanics of building, such as sustainability, innovation, human skills as well as the marginality linked to the rental service. The role of modern rental in Italy can certainly rise, provided that it place itself as a strategic choice in the construction chain and not as a main support for companies during work peaks. Let’s say that rental in Italy is still very fragmented and that the basic legislation does not recognize the figure of the renter. Companies that deal with rental are developing from traditional machine suppliers for occasional needs to the role of general provider. This involve certain obligations in order to remain on the market, such as the need to digitize, train new professional figures, oversee safety, as well as take charge of the ecological transition. The role of digitization When speaking about rental in the construction sector the real impact of digitization should be taken into consideration. Digitization improves the customer experience, it fully support all phases, maintenance, fleet management, credit access control or insurance coverage. The advantages go far beyond the automation of processes. A greater efficiency leads to the supply of well-timed services and also to the improvement of the economic margins. But not all players in the supply chain are interested and willing to approach the digital. In this sense the high average age of the sector plays an important role. The importance of training In order to improve the rental sector and ensure that operators go from “rent-of-cars” to value creators, new skills are needed. Despite a youth unemployment rate of 30%, there are few technicians in Italy. According to official studies conducted in Italy, Portugal and Spain, it emerges that young people are unwilling to take professional courses because they think these are prerogative of those who have no aptitude for study. In the coming years, only operators who will take up a reputation’s repositioning process of the technician role will enter the construction market. That is to say the one who has a strong aptitude for problem solving, as well as increasingly specific skills, such as predictive maintenance, mechatronics, digitization. This aspect is directly related to rental in construction, because its effectiveness also and above all depends on the ability of the companies to offer an articulated and high-level professional service, mediated by trained professionals. Otherwise the only indicator will remain the rental price. More than just an accessory service For a truly modern rental you need to get out of the here and now mentality and have a more forward-looking approach. Just think of the investments in personnel training and the consequent value that comes from it: a well-trained technician can both solve a very normal machine downtime and support the customer in preparing a long-term rental plan as an alternative to purchase. This way the value of the service justifies a higher ranking. The renter is now called to raise the value of the service both towards its employees and towards customers, suppliers, stakeholders. Therefore it also has a social role. The attention to sustainability and safety, the growth of people's skills, digitization, the exchange of ideas between people involved allow us to give a different interpretation of the sector: from mere negotiation to a real cultural change. Long-term rental and the construction sector: who pays for it MMT vehicles are among the top cost items for construction companies. Long-term leasing can, if well managed, improve the company's bottom line while having regular access to new vehicles. As corporate fleet managers find it increasingly difficult to navigate a maze of increasingly complex tax systems and new vehicle designs powered by alternative energy, long-term leasing provides a number of answers to these challenges. This aspect primarily concerns medium-small companies. While large companies in the construction industry have known and used the advantages of long-term rental for a long time, small and medium-sized companies are only just starting to take advantage of this concept. Long-term leasing can save a fleet acquisition budget, provide constant availability of up-to-date and well-maintained equipment, and result in a fixed budget item in the form of vehicle rental costs. The latter are incorporated in the management costs, with consequent advantages for the company's budget. Furthermore, the rental company becomes the single point of contact for the management of all vehicles, with centralized and predefined billing and service levels at the time of signing the contract. The principles of rental in the construction sector Renting construction equipment is simple. A construction vehicle is provided in exchange for a monthly rental fee that includes financing and services.Adding a new vehicle to your fleet is only convenient if you can amortize the investment costs in the long term. In a small or medium-sized company, however, the purchase of earthmoving machines represents a high cost both at the time of purchase and over time, with maintenance and management costs. Not to mention that for each specific activity it is good to use the right mean: and this would mean having a well-stocked fleet of machines! Renting therefore represents an advantage, because it avoids the most onerous expenses and allows you to take possession of the most suitable vehicle for carrying out certain operations for a limited period of time. Flexibility is called From the first advantage comes the second: flexibility. As already said, thanks to the rental of earthmoving machinery it is possible to use the right machinery in case of specific needs, and moreover only for the established time, without having to invest great capital. Renting instead of buying an earthmoving machine also allows you to bypass some activities, above all ordinary maintenance. In fact, the rental includes full service maintenance and assistance. This means that, faced with any problem, companies can always take advantage of someone ready to intervene.

-

Spare Parts

A new look for Idromeccanica Ramtec's hydraulic hammers

At bauma also the Tracker data transmission device and the CR45 compactor and the series of magnets. The Italian company Idromeccanica Ramtec share with bauma 2022 visitors what’s new about attachments and the integrally attachments new look. Three of the best selling models of Idromeccanica Ramtec’s range of hydraulic breakers are displayed: RT 115, weighing 1000 kg, suits the latest machines from 12 to 20 tons. It will be featuring the special “X-Profile” 115 mm tool. It’s the so called self-sharpening tool which is recommendable for particularly hard and abrasive material. The crisscross shape and grooves allow the material to easily exit, therefore, improving and making penetration faster, avoiding the tool to overheat, reducing wearing meaning a longer life of the tool. RT 118, featured by a simple design and being quite easy to maintain, weighs 1200 kg and fits any machine from 14 to 24 tons. It’s particularly suitable for reinforced concrete demolition works, channelling and tunnelling. The heavy duty RT 150 made for hard work weighs 2400 kg and suits machines from 27 to 35 tons. It’s featured by a sturdy casing, high performance and productivity with low vibration and noise emissions. The RT 150 is displayed at Bauma with the automatic greasing device which doesn’t need any kind of hydraulic installation and just simply works with the vibration of the breaker and is very easy to use. All the operator has to do is to replace the cartridge. Idromeccanica Ramtec display at bauma 2022 also one of the most popular hydraulic compactors. The CR 45 which weighs 430 kg and suits backhoes and excavators from 5 to 9 tons operating weight. The company’s hydraulic plate compactors offer an advantage unlike the ones on the market as the lower plate is simply bolted on making it very easy to bolt on a post-driving plate, therefore, becoming a two-in-one attachment. The CR45 is displayed with the new universal mechanical quick hitch which allows the operator to change attachments quickly and efficiently. Idromeccanica Ramtec recently introduced magnets in its range of products as they detected the need of demolition companies to handle scrap in a more efficient, sustainable and productive way. They will be showcasing one of the most popular models which is the HM 95 magnet with chain but they also offer other models with top brackets and teeth according to different needs and applications. Their magnets are highly appreciated as they allow the operator to lift all metal scrap making the construction site safer turning waste into profit. Among the innovations presented at the fair, there is the new TRACKER device that helps renters and operators to track accessories and receive a complete overview of their position and operating times to keep everything under control remotely. Finally, Idromeccanica Ramtec display at bauma spares which are part of over 6000 non original replacement parts they are manufacturing for the most popular brands breakers among which Atlas Copco, Epiroc, Furukawa, Kent, Krupp, Montabert, Tramac, NPK, Rammer, Allied, Soosan, Toku and many more. Click here and discover more about Idromeccanica Ramtec.

-

Crane

Raimondi Cranes: the new T187 tower crane

Raimondi Cranes with the launch of the T187 inaugurates a truly unprecedented range of tower cranes featuring performance and modularity Raimondi Cranes has renewed the range of topless tower cranes, in particular the T187 model. This new crane represents a big step forward for the manufacturer as it inaugurates a new range construction process which represents the basis for the entire Class 110 series. One of the major changes implemented by Raimondi is a new design and development approach right in the production system of its tower cranes. The modularity of the mechanical and carpentry parts combined with the interchangeable elements has facilitated the mass production of a new family of eight cranes, designed on the basis of the most recent lean manufacturing techniques. Additional benefits are the ability to deliver higher quality standards and minimize site downtime while also reducing maintenance costs and spare parts inventory for rental companies. A perfect equipment for rental With all improvements in range, speed and headroom, the T187, like the entire Class 110, has been designed with and for rental companies. The variety of choices, 8 and 10 tonnes, II/IV pulling or permanent two lines, allows renters to meet clients’ needs and face different projects. Boom length of 67.5m and tip capacity of 1.61 tonnes in UltraLift allow the T187 to fit into premium lift systems. The T187 is therefore suitable for the construction of medium-high buildings, thanks also to the maximum lifting speed of 115 meters per minute (in the version with 37 kW hoist) and the drum capacity of 620 m. All the new winches are also equipped with the Down Over Speed (DOS) system which allows a substantial increase in intermediate speeds when descending. Maximum equipment management Each machine is now equipped with a central processing unit that guarantees operation even in extreme environmental conditions. Raimondi's new ConCore control system, thanks to electronic sensors and redundant controls, allows faster setup, extremely precise calibrations as well as targeted identification of any problem. The first in Belgium Raimondi has already provided an example of the T187 tower crane to ABHR, a Belgian construction company. The T187 was chosen for its best-in-class characteristics in terms of lift capacity and speed, also thanks to the new ConCore control system. The technical installation process included the first phase of preparation of the jib, counter-jib and slewing unit with cabin which took place on the ground, followed by the assembly of the 4.5 m HEB700 base, the assembly of the 1.5 m series mast elements and the final assembly at height of the pre-assembled muzzle elements on the ground. All supported by the use of a 200-ton mobile crane. “We are thrilled to be the first European construction company getting a machine from the new Raimondi series. We considered the lifting capacity and speed, as well as the weight-optimized components, which enable our installation procedures, as the most important characteristics in choosing this model,” said Max Van Gompel, General Manager of ABHR.

-

Italy@Bauma

MP Filtri: Patch Imaging Kit and filter recalibration service

MP Filtri offers a new Patch Imaging Kit dedicated to end customers and a filter recalibration service MP Filtri for 2023 offers two significant new entries presented in preview at the last bauma: the new Patch Imaging Kit dedicated to customers and an interesting service for the recalibration of the MP filters themselves. These are two complete solutions designed for an increase in the performance of the filtering systems for greater operational continuity of the hydraulic systems. Fluids’ contamination monitoring MP Filtri's Patch Imaging Kit was designed as a supplement to MP Filtri's inline portable particle counters offering highly accurate, real-time inspection of contaminants in fluids. The new Patch Imaging Kit includes a digital microscope that gives operators the ability to evaluate these particles under a microscope and identify potential sources of contamination. The kit allows performing rapid and accurate tests on fluid samples and, by capturing contaminants on a membrane, it allows to carry out detailed analyzes through the digital microscope included in the kit, measuring, recording and offering the possibility of observing and evaluating individual particles. By being able to visually evaluate their appearance and composition, it thus becomes possible to isolate the cause of wear within a system. For example, the presence of rubber particles suggests the decomposition of the hose, while the high content of metallic elements reveals the wear of pumps or mechanical components. By identifying the specific causes of decomposition, maintenance personnel can thus replace worn components, protecting complex systems, extending the life cycle and reducing maintenance costs and downtime. Patch Imaging Kit: how it is The new Patch Imaging Kit consists primarily of a high-performance digital microscope, with magnification up to 400x which is combined with highly sophisticated software (which runs on the Windows operating system) that allows the measurement and analysis of single particles. The Patch Imaging Kit is a comprehensive test that facilitates rapid and accurate sampling, easy to use and without the need for specific training. Recalibration MP Filters HQ Recently MP Filtri has also launched a new machine: it is the new test bench dedicated to the recalibration of contamination monitoring devices. The recalibration of the meters is carried out on the basis of ISO 11171 and the test bench is certified according to ISO 11943. But why is the recalibration of a particle counter necessary? The MP filter counters work with light beam extinction technology. The particles of solid contaminant present in the oil are counted and classified by size based on the electrical signal detected by the light photo-receptor which recognizes them as shadows. Recalibration verifies and realigns photo-receptor operation. The test bench has the function of maintaining the test liquid (an oil with verified characteristics) in a constant condition of calibrated contamination provided that the size and quantity of the particles of this suspension are known in advance. How does recalibration work The MP Filtri recalibration software automatically adjusts the electronic counting system, realigning it to the target value. The combined test bench system together with the dedicated software also performs diagnostics of all the operating characteristics of the meter and, where provided, indicates which parts or components need to be replaced. Always perfect monitoring This system allows the customer to return the device intact, recalibrated and complete with all available updates, but above all quickly, considering that the recalibration service is performed completely within a week. The customer can personally book the service online, through the dedicated section on the MP filter website. Once all the checks have been completed, the customer is issued a calibration certificate which is valid for one year with the purpose of certifying that the product works correctly and that the readings performed are confirmed.

-

Aerial Platform

CMC: the new aerial platforms for 2024

For 2024 CMC is releasing two new tracked platforms: the CMC S27 and CMC S30 introduced for the first time at bauma 2022 Starting from bauma 2022 CMC presented the latest models among its range of tracked aerial platforms: the S27 and the S30. The S27 is the smallest one and offers performance that ranks at the top of the specific category. The S30 is the new entry of the Apulian manufacturer with top performance and premium technology. During all trade fair events dedicated to the construction and lifting sectors held in 2023 CMC showed its highlights. The Apulian company took the opportunity to show operators a preview of the latest generation technologies and solutions confirming itself as a specialist for aerial access and movement of people on self-propelled tracked vehicles. Brand new at CMC 2023 therefore the manufacturer is aiming for the CMC S15, CMC S18F, CMC S23 Lithium, CMC S23 Diesel (powered, precisely, with an endothermic engine) but above all, as anticipated, two completely new products: the CMC S27 and CMC S30, introduced for the first time at bauma 2022. The two new platforms, both equipped with a double lateral arm in addition to the jib, can reach an operating height of 27 and 30 meters respectively. They have been improved by a good two meters more than the S25 and S28 models they are replacing. The outreach was already among the largest in the category and increases by 1.40 meters making it the largest ever. In addition to these upgrades CMC has introduced all the characteristic elements of other components of the Double Performance family that allows for very high performance in many technical fields. One of the advantages of the new S27 and S30 is therefore a very high maneuverability guaranteed by an automatic driving and control system. It is a very advanced technology but with a simple and intuitive use. The other fundamental aspect is the ease of transport thanks to the low weight. A positive factor due to the choice of high-performance materials and compact dimensions, so much that the two machines can in fact pass through a standard door. These specific points allow for high efficiency and reliability in any operating condition. The multiple stabilization areas, managed by the CMC Self Control System, allow in fact to operate in optimal conditions and also in negative conditions. At the end it is necessary to add the high lateral outreach which is astoundingly operational even with a reduced stabilization area. The growth of CMC The CMC brand has long gone beyond national borders and its aerial platforms are now sold in more than 30 countries worldwide and on all five continents. The company gives the utmost importance to quality controls, carried out in every phase of the processes certified according to the UNI EN ISO 9001 standard. All its platforms are assembled with highly performing components, while the painting department performs up to 14 operations for ensure maximum resistance of the structure to wear and corrosion. The different aerial platform models are subjected to strain gauge checks and structural analyzes that simulate thousands of work cycles to ensure perfect efficiency over time. The CMC platforms also own the specific CE certifications for Europe, AS 1418 for Australia and TUV America for the US and Canadian markets. S27 S30 Max working height 27,3 m 30,3 m Work in negative -6,8 m -6,7 m Maximum reach 15,4 m 15,4 m Height to floor level 25,3 m 28,3 m Max capacity in the basket 230 kg 230 kg Basket measures 1,7 x 0,7 x 1,1 m 1,7 x 0,7 x 1,1 m Basket rotation +/-90° +/-90° Turret rotation +/- 200° (400° continui) +/- 200° (400° continui) Total mass 4.094 Kg 4270 Kg

-

Perforatrici Elettriche

Soilmec: the new full electric drilling rigs for 2023

In 2023-2024 Soilmec plans to relaunch its range of machines for large construction sites, which includes a full electric micropile machine Soilmec has lined up for the years 2023 and 2024 a series of innovations that underline the technological variety of this international company based in the Romagna Region in Italy. This year means for Soilmec the entering into a technological transition, as announced during the latest edition of bauma with the launch of his first fully electric compact machine. The new Blue Tech range with the SR drilling rigs Soilmec’s news for this year also refer to the more traditional product’s segments. A new generation of SR drilling rigs is coming up within the Blue Tech range of products. This new version offer an increase in the productivity and more flexibility, reducing at the same time operational costs and emissions, a higher levels of comfort, ergonomics and safety. The improvements focused in particular on optimizing power transmission and minimizing energy dissipation, paying particular attention to the main components of the machine which are normally involved during the work cycle. The diesel engines are equipped with the start and slow system, which automatically adjusts the rotation speed according to actual needs, improving combustion and cooling efficiency with less noise pollution. The rotary heads have been developed with a wide range of solutions to reduce losses and increase performance. The top level for medium-sized machines is the SR-65 model, and the new SR-125 platform presented in preview in its Blue Tech form. Hydrocutters with the SC-135 Tiger The SC-135 Tiger represents the top product of Soilmec’s hydrocutters. Designed to optimize productivity and reliability, the machine is equipped with the HDD system and has a platform with reels on the machine body. This are installed in series and aligned with the head in order to facilitate a perfect movement of the hydraulic hoses and mud in the different range of activity. Reliability is guaranteed by a double hydraulic system: one dedicated to the excavation module and the secondo to the basic machine. High-pressure filters and an accurate drainage management with dedicated tanks are also part of it. Transport is easy even with 200 tons of operating weight thanks to the assembling in single 45-ton load transportable modules. The ideal combination is the one involving the new Soilmec SH-35 excavation module. The electric SM 13e Among the iconic micropile machines models of Soilmec and in addition to the well-known SM-22, comes the first full electric machine, the SM-13e. In the company's goals, the SM-13e is the first step for the development of an entire range of electrified machines for micropiles, poles and cranes. This represents the response to an increasing demand of the market for reducing polluted and acoustic emissions, increasing efficiency and reducing operating costs. The brand new machine is an evolution of the first electric motorized ones for drilling and consolidation works in internal environments and in tunnels, such as the ST-20, the ST-60 and the SM-5E. Not a simple replacement of the heat engine with an electric one, but an electric power supply in line with the latest developments such as the presence of permanent magnet motors, alternative lithium batteries for power supply and control inverters. This turns out to be very far from the previous ones equipped with three-phase asynchronous power supply motors. Visit Solimec page

-

Low Emission

“Next Generation” construction: ZERO EMISSION goal

Construction and mechanics in the building sector are aiming for an energy transition with a zero-emission goal, especially for operations on urban construction sites The development in the technology applied to the earthmoving machinery sector will tend in the coming years more and more to an energy transition with an explicit goal of zero emissions. This in order to meet the gov-ernment objectives set in terms of pollution. The engines’ function that activate the mechanical and hydraulic devices of the construction equipment can only tend towards electricity, even if there are not only engines as the target of energy transaction technolo-gies, but also many of the components that operate booms, buckets, lifters and many other elements that make up mechanical systems. Net of this engineering trend, the demand for machines that can work without restrictions in inhabited cen-ters or in sensitive areas with limitations on noise and exhaust gas emissions is increasingly high. Some market leaders in the earthmoving sector have already been selling for years almost complete ranges of electric machinery, wheel loaders and compact excavators, machines that allow to work and move materials even inside buildings. However, the decarbonisation of machinery is not only driven by ecological reasons, but above all by the need to be able to work in a less impactful, more silent way and without the emission of dan-gerous gases, harmful to health. Technically, the torque of the electric motors guarantees high-level perfor-mance to the new professional battery-powered machines, with a work quality often equivalent to that of the internal combustion engine vehicles used up to now. Certainly, in parallel with the necessary development of electrified technical solutions, it will also be mandatory for the user to have an adequate battery recharging infrastructure, which allows working with continuity, effectiveness and general cost efficiency. For this rea-son, it will be necessary for companies to turn to professionals, partners and consultants who are able to guide them on the right electrification path for their fleet of vehicles. Electric work machines, today, still have a purchase price of about double that of traditional ones, but the TCO (Total Cost of Ownership) is definitely down, thanks to the reduced maintenance costs required over the entire life cycle of the machine. The advantage of electric Electric motors, being in a mature technological stage in their development, have obviously been elected icons of energy transition because they are first of all silent. This feature makes them suitable for use in areas where there are restrictions on noise for machinery. They also protect operators and the environment from exposure to direct exhaust fumes, thus allowing many work processes to be carried out even in places with poor ventilation. Another advantage is that electric motors are considered low-maintenance and quick to re-pair in the event of breakages or anomalies, also thanks to constant monitoring of their operation, carried out by predictive diagnostics of malfunctions. Skid steer loaders, fully full electric Some manufacturers have already launched compact machines for full electric handling on the market, both for traction and for the implementation of operational movements. These are projects compatible with work in urban construction sites that do not require excessive power and total masses on the ground, characteris-tics that go hand in hand with the need for rapid battery charging and significant autonomy for adequate work cycles. The battery pack, now almost always lithium ion, is on average around 60 kWh, which allows these machines to operate continuously for about four to five hours. The payload is around 1,200 - 1,400 kg. The movements are obtained through electric motors or actuators and therefore, unlike conventional machines but with elec-tric motorization, it does not require practically any fluids. The only liquid on board is therefore the ecological refrigerant. The evolution of battery vibratory plates Other brands presented electric-based solutions for road construction, such as battery-operated reversible vibratory plates with direct drive. These are attachments that can use a hydraulic adjustment system to change direction. Other manufacturers have instead launched, still in the field of machines dedicated to compaction, models powered by a maintenance-free lithium-ion battery with sufficient capacity for an entire working day. The op-erating principle is that the energy released by the traction and vibration motors during braking is used in re-covery. This system would also significantly reduce noise emissions, making the rollers suitable for all areas requiring particularly quiet compaction. Still in the field of maximum noise reduction, prototypes are being launched that use oscillation to achieve high compaction in a totally silent manner. Fully electrified concrete mixers Also in the concrete sector, the trend is towards the launch of prototypes of fully electric concrete transport machines. The battery of these vehicles has a capacity exceeding 350 kWh. Translated, it means that one charge is enough for five or six trips in urban areas, basically a whole working day. Full recharging is done throughout the night thanks to dedicated DC charging stations. Lifting and the propulsive transaction An operational field of construction that was among the first to look at electrification is certainly that relating to lifting. An interesting project is the one that on a traditional crane provides a zero-emission electro-hydraulic modular system, which can be transported together with the crane itself. The electro-hydraulic module can be used for all crane functions as well as for operating the hydraulic conditioning system. In addi-tion to guaranteeing zero-emission and low-noise operation, such a system also has significant cost ad-vantages: the intelligent electric motor control system ensures that it uses only the amount of electrical ener-gy necessary to perform the required functions. In this way, lower operating costs are obtained compared to those of using a diesel system and furthermore the operating hours of the engine are reduced. The electro-hydraulic system is powered from the mains via a 400 V / 63 A plug. On the go, the crane can transport the system to the construction site with a trailer. Alternatively, he can carry it with a carrying frame in the back. In short, it is not necessary to transport the system separately.

-

Construction Site

Earthmoving machinery market shows resiliance in 2023. But in 2024?

The construction equipment market is holding up and it looks like it will keep up until the end of 2023. Big uncertainty for 2024 is announced The construction equipment market is still safe for now and the trend continue until the end of 2023. From 2022 general economic conditions are changing for the construction machinery as well as for othe industrial sectors, but less than the forecasts released at the beginning of the year. Inflation is playing a important role together with the continuous interruptions in the supply chain and the economic fallout following the war in Ukraine. For the Italian and European construction industry Russia is an important export market. The 40% drop in sales in Russia has been however largely replaced by other exchange flows, as the figures show. Nevertheless, the resilience of the construction machinery sector continues to be the cornerstone for the entire sector. The annual economic report of CECE (Committee for European Construction Equipment) published at the beginning of the year are particularly significant. The European Federation of Construction Machinery has traced some important trends to be kept in mind when trying to predict what will happen between now and the end of the year. The European construction equipment market in 2022 The CECE report shows that in 2022 the sales of construction equipment in Europe were practically at the same levels as in 2021 and recorded only a minimum drop of 0.6%. This confirmed the solid demand in Europe: without the continued supply chain disruptions, the market would have registered another year of growth. Sales in Europe excluding Russia - where the market fell by 37% due to Western sanctions - increased by almost 3% in 2022. Other global regions of European exports also maintained a strong pace. By the CECE Business Barometer, the end of 2022 was evaluated as positive and the confirmation of this positive trend in the first half of 2023 leads us to think that this situation will continue until the end of the year. But uncertainties about inflation and interests unfortunately predict an unstable macroeconomic framework. Maximum caution for 2023 There have been significant changes in Europe in the last six months of 2023 that have had a major economic impact on construction: the war in Ukraine and the anxiety it has caused across the region; changes by central banks; sharp increases in interest rates in parallel with the credit crunch. Last but not least, the problems with the availability and cost of construction products with a great impact on housing, both new construction and renovation. What will happen between now and the end of 2024? Difficult to answer this question. We are certainly experiencing a period of transition for the industry which should lead to a return to growth in 2024. According to Euroconstruct, we can expect two difficult years for the construction sector throughout Europe, with a growth forecast of just 0. 2% in 2023 and 0% in 2024. A return to growth in production looks a little more uncertain before 2025. Construction production in the EU is expected to continue increasing until the end of 2023, but at a moderate pace. The situation of the Italian market Let's start from 2021. In that year, Italy was the strongest market in Europe, with production growing at 12.1%, driven in part by EU subsidies. Subsequently 2022 was an exceptional year for the construction sector with activity levels approaching the peak levels reached in 2007. The construction market benefited of significant private resources such as accumulated savings by households and businesses in both 2020 and 2021. Alongside this, the huge public resources (tax incentives such as the Superbonus as well as the national fund recovery plan) have supported the activity. However, a trend reversal is expected in 2023. In addition to the surge in prices within the sector, construction will cost between 15 and 20% more than in 2019 and inflation has also started to affect housing prices and demand. 2023 is therefore shaping up to be a year of transition, marked by a general slowdown but overall production growth is expected to remain positive at 0.9%. This will lead to an uneven situation among the various sectors which will go from -9% for the residential sector for maintenance works to +41.7% for new public works. From 2024 the market is expected to slow down significantly. Total investment is expected to decline by 7.1% and residential renovations and maintenance are expected to decline by 22.6%. Incentive programs have been the main driver for construction work but are set to be scaled back. Expectations for public works are different, but to date a question mark remains on the realization of the works subsidized by the National Plan, and on the ability of administrations and businesses to meet the objectives expected by the European Union. The challenges concern not only the design and execution of the works but also the procurement and cost of materials. The construction machinery market in Europe and worldwide The resilience of the construction equipment sector is well established and has always been supported by a stable business situation in most sectors, but it is still surrounded by a toxic mix of inflation, constant supply chain disruptions, and worries about the world economy. At the beginning of 2023, the majority of companies report a positive business situation and have positive expectations for the near-term future. In the February survey, construction equipment manufacturers were once again the most optimistic group. When looking at business expectations by region, manufacturers view North America and, to a lesser extent, Latin America as the best prospects. In Europe, ambitions focus on Germany, France and CEE markets as the best opportunities. The perception of the Russian market, which is still at the bottom of the list in terms of market expectations, is taken for granted. The industry's backlogs have reduced in part due to greater willingness to build and deliver machines. However 60% of European producers still report a backlog of more than four months. This confirms that at least the first half of 2023 has been safe while the second half of the year could lead to a more challenging scenario. Higher interest rates due to current inflation in Europe have a significant impact on the outlook for the construction industry, especially the residential sector, and this may affect sales of equipment that is used in this sector as well as the gardening and landscaping sector which will likely see weaker demand after many years of booming sales. Civil engineering however will still benefit from public investment programs in many European countries. Assuming that the geopolitical scenario will not change this year, the European market is expected to record a single-digit decline in sales. But that doesn't necessarily mean that European manufacturers will face a loss of revenue, also because markets – particularly in North America, Latin America and the Middle East – remain positive.

-

Italy@Bauma

Definitive CLM: premium loading ramps for construction

Definitive CLM designs and produces aluminum loading ramps for the construction sector. Compact construc-tion’s logistics quick and easy with the small series. Definitive CLM is specialized in the design, production and sale of high-performance aluminum loading ramps dedicated to earthmoving machinery. The range includes ramps for wheeled, rubber or steel tracked vehicles and maintenance stations. The quality of these tools is essential, the ramp being a fundamental element for the logistics of all industrial vehicles and for safe loading and un-loading phases. Multipurpose and multifunctional equipment Definitive CLM loading ramps are used in various sectors including earthmoving, loading and unloading of mini-excavators, mini-loaders, wheeled and tracked excavators, as well as backhoe loaders. They are used for handling of hydraulic and aerial platforms, telescopic lifts and motorized wheelbarrows. They are often re-quested from municipality and green maintenance companies for lawnmowers, tractors and motor hoes. Handle and use of aluminum ramp Aluminum loading ramps are simple equipment but require some good rules of use especially for their han-dling and installation. Before positioning the CLM Definitive ramps the means of transport need to be safely parked on a flat and solid surface. Tipper body equipped vehicles must be fixed in a horizontal (lowered) posi-tion. Locking of the ramps on the vehicle must follow the given model. If a fixing pin is used it must have specific requirements in terms of dimensions and materials depending on the machine to be loaded. Lightweight and resistant materials Definitive CLM uses extremely high-strength 6082 aluminum to guarantee quality and maximum performance over time.Its main feature is a low specific weight equal to a third of that of steel. The structure of these ramps also re-mains unchanged over time thanks to a very thin layer of oxide which prevents oxygen from penetrating and corroding the underlying material. Definitive CLM uses the DOUBLE T profile which guarantees the highest value of resistance and flexing with the least surface area and therefore with the least weight. Precautions during loading A good practice is checking the weight of the vehicle which must comply with the capacity before moving it. It is also necessary to check the distance between the ramps and make sure that the width of the ramp is equal to or greater than the width of the wheel or track of the vehicle to be moved. When moving the vehicle it is necessary to get on or off at a speed between 1 and 2 km/h without carrying out aggressive maneuvers to adjust the direction avoiding sudden acceleration or braking. The range for compact earthmoving machines Among the most requested ramps in the Definitive CLM catalog for the construction sector are those dedicat-ed to compact vehicles, both wheeled and tracked. This is a segment of earthmoving machinery that is ex-tremely sensitive to the speed of loading and unloading on vehicles with a gross vehicle mass of 3.5 tonnes or light trolleys. In this type of machine a high frequency of movement from one site to another is necessary even several times a day. Series 55/75/85 The entry level of Definitive CLM is represented by the 55/75/85 Series. It is suitable for loading medium-light weight vehicles such as construction machinery, agricultural and garden equipment or garden tractors equipped with rubber tires or tracks, as well as minidumpers tracked vehicles with a maximum load capacity of 3.6 tons per pair. The ramps of the 55/75/85 series are made only without external edges but can can be provided with edges on request. These types of ramps are often combined with transport vehicles such as vans and trailers for cars and commercial vehicles. The maximum capacity is 3.6 tons and the standard surface of the ramp equipment allows it to be used with pneumatic wheels and rubber tracks. The surface can be replaced with a specific flat and non-slip surface spe-cific for solid wheels and/or small diameter like trolleys on request. Series 100/115 Going up in load performance you move on to the 100/115 Series. These ramps are suitable for loading medi-um weight vehicles such as mini excavators, skid steers, construction machine loaders, dumpers equipped with tires or rubber tracks up to a maximum capacity of 4.5 tonnes per pair. These ramps are made as standard with external containment edges making it easier for the operator to go up and down. The same ramps can be supplied without edges on request. Series 125 The top of the range is represented by the 125 Series. These ramps are suitable for loading medium weight vehicles (such as midi-excavators, skid steers, high performance loaders) with tires or rubber tracks up to a maximum capacity of 6.4 tonnes per pair. The 125 Series ramps are produced with both external standard containment edges and without edges. The standard surface of the Definitive CLM Series 125 ramps allows them to be used with pneumatic wheels and rubber tracks. Upon request the surface can be replaced with a special reinforced surface.For loading forklifts and aerial platforms with solid wheels the version without edge and with reinforced sur-face is available.

-

Concrete Preparation & Processing

Carmix 45 EVO: off-road self-loading concrete mixer for 2023

The new self-loading Carmix 45 EVO concrete mixer is the innovation of the Venetian manufacturer for 2023 with a new cab, new control functions and a brand new Perkins Stage V engine Carmix expands its range of off-road self-loading concrete mixers with a new entry: the Carmix 45 EVO, powered by Perkins 904J-E36TA Stage V engine and capable of guaranteeing 120 HP (90 kW). The production of 6,050-litre drum is rich and guarantees 4.5 m³ concrete, while the loading shovel has a capacity of 600 litres. It is a compact off-road mixer, evident to use and with low maintenance costs for producing concrete on small and medium-sized construction sites. The user-friendly driving system, the compact dimensions and the 4x4 steering four-wheel drive allow in fact to move even in small places and to travel easily on rough and uneven roads. English engine, German transmission The important innovation concerns the new 90 kW Perkins 904J-E36TA Stage V engine, optimized in terms of consumption and adaptation to the operating cycles of a wide range of applications. For the hydrostatic transmission and drum rotation, Carmix opted for Bosch-Rexroth equipment with two variable displacement axial pumps. The machine is also equipped with two Bosch-Rexroth gear pumps for the two joystick distributors of the loader and services. Brand new cabin Compared to the other models, the new Carmix 45 EVO features a new and restyled control panel in ABS material, with a dedicated Joystick to control the loader and a large display to view the loading phases. Thanks to the reversible station with automatic circuit inversion, the operator can drive and control the vehicle both from the front and from the rear. Concretes accurate to the gram In the Carmix 45 EVO the control and monitoring tools are of great importance: the new concrete mixer is in fact equipped with the Mix Made system which allows to dose, weigh and program any material to create a perfect mix-design on site. The direct control of the elements right where the mixing takes place (including the real weight of the water for an optimization of the w/c ratio) guarantees greater precision and a reject below 3% of the weight as in the most sophisticated concrete plants without counting real verifiability of the finished product. Model Carmix 45 EVO Max concrete production 4,5 m³ Drum capacity 6.050 l Loading capacity 600 l Engine Perkins 904J-E36TA Stage V, @ 2.400 rpm Power 120 CV (90 kW) Weight 7 t Transmission Bosch Rexroth Tire 16/70-20 PR14

-

Bauma

bauma 2025 on the starting blocks

The road to bauma 2025 as a common path for all companies called to contribute to the growth of the community. MONACOFIERE MF alongside the sector to support its growth and visibility thanks to the ITALY@bauma portal Editorial from Davide Galli Managing Director di MONACOFIERE Less than 6 months have passed since the end of the last bauma edition and we are still receiving lots of positive feedback from the Italian companies that took part in the event. Both old and new exhibitors, buyers, media representatives: everyone was clear how much the personal meeting is fundamental for laying the foundations for a profitable collaboration. The organizational effort was enormous despite the premises presenting some unknown factors, one above all, the dates of the event. Traditionally held in the spring months in April, the show was then rescheduled in October for reasons that we all know and hope they definitively belong to the past. After some initial hesitation, it became clear this was the right choice from which the entire supply chain could benefit, allowing all interested parties to take advantage of the opportunity offered by the event. The initial expectations have been far exceeded and bauma has confirmed itself as a privileged communication platform where products, technologies and solutions can be presented. Following this positive feeling, we are now ready to restart with preparations for the next edition of bauma to be held from 17 to 22 April 2025. The organizational machine has already started and Italian companies can register now and send their requests . Yes, because bauma already starts today and companies are now gathered to plan different activities that make their participation as profitable as possible. With the aim of supporting this activities, last September we created the online portal ITALY@bauma, a tool dedicated to Italian companies participating in bauma to promote their presence on international markets not only during the physical fair but 365 days a year. More than 500 companies under the same roof are rarely to see and they deserve a stage that offers due prominence, the construction machinery industrial sector being one of the most important in our country. In recent months we have worked hard to offer Italian companies a product, the ITALY@bauma portal, which now presents itself in a renewed shape. First of all, a bilingual edition, English and Italian. Suggestions came directly from the exhibitors, who underlined the importance to get advantage of the portal also in their native language. Born as a natural projection of the Italian companies participating in the physical event to promote their image and products abroad, the need arose to offer a product that could also be used by the various Italian clients: buyers, specialized operators and all interested parties in the world of the buildings. The goal is to provide updated information and grow a community with everyone's contribution. Another news is an improved layout, which highlights much more the contents. The aim is to achieve a daily networking tool and making it more usable to a large audience. Already in the coming weeks we will have the pleasure of hosting on our channels an exponent of the Italian association and manager of an important Italian company. We will discuss some hot topics of the moment, that will be certainly of interest for all the community. We therefore invite everyone to stay tuned and do not miss our updates. Walk the road with us towards the next bauma 2025!

-

Construction & Commercial Vehicles

Rotair: the turning point into compact compressors

Rotair launches a new range of compact electric and hybrid compressors and new product lines for light dem-olition and site handling Rotair, a company based in Caraglio (CN), has announced the international launch of its compact portable air compressors: the Mdvn34E and the Mdvn32B. Rotair is an Italian industrial reality specialized not only in the design, production and distribution of high-tech portable air compressors, but also multifunctional dump trucks and hydraulic breakers under the ELGi Equipments Limited brand for over 60 years. The two Mdvn34E and Mdvn32B compressors are already highly appreciated by operators for their flexibility, sustainable electrification and the ability to intervene quickly and flexibly within the site, thanks to a dual power supply which makes them adaptable to different operational needs. A sort of hybrid The design basis is a structure with both an electric motor and an internal combustion engine able to develop compressed air. The system is designed to contain a generator giving the very important advantage of remaining within the strict european regulations on emission. Rotair's compact portable compressors also have european road approval which allows them to be towed and used throughout the European Union. Mdvn34E: connectable to the main electrical supply In the Mdvn34E model, the unit was created to offer construction sites 3,400 litres/min compressed air, without the use of internal combustion engines, to work in those municipalities and sites where diesel engines are limited in use. Its design allows to be connected to the building site's electrical main supply network and allows the air flow to be modulated according to the user's request. Mdvn32B: the portable one On the same chassis and bodywork, Rotair also offers a variant of the 40 HP gasoline engine able of delivering 3,200 litres/min at a constant of 7 bar, within the Stage V emission parameters. Performance remains the same or even better than Stage V diesel engines with considerable savings on the purchase price and on the management of the compressor itself. “Rotair has always been proud of designing and producing innovative solutions that meet the current and future needs of its customers. Our new portable electric compressor, Mdvn34E, is leading this evolution towards cleaner, more convenient energy for optimal performance and reliability,” said Giuseppe Donadio, chief executive officer of Rotair. “This approach apply also to the Mdvn32B portable fuel compressor, which remains well below Stage V emission benchmarks.” A 2023 full of news Rotair products also cover the demolition sector, with a range of light hydraulic hammers. Among these is the new OL95ST for 2023, featuring a completely redesigned and engineered design with reduction both in production costs and in the final price for the customer. Furthermore, ROTAIR will expand in 2023 its product range with two new products: the VRK Fibra Plus compressor, designed for the laying of last mile fiber optic cables and the Rampicar dump trucks (in the R70 and R100 variants) equipped with completely hydrostatic transmissions to facilitate easy handling for the most demanding work requirements in renovation sites and civil engineering works.

-

Crusher

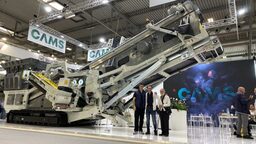

CAMS Centauro XL 150.69 APR: Revolution is coming

Build by CAMS the new Centauro XL 150.69 APR a mobile crushing and screening plant that recovers 100% of the material, arrives on the market CAMS announce the launch of its Centauro XL 150.69 APR, a high-performance mobile crushing and screening plant. The equipment, part of the Centauro family line which is characterized by crushing and screening equipments capable of combining a shredder, screen and magnetic iron separator in a single machine it's particularly suitable for heavy duty uses. The Centauro XL 150.69 APR system represents an innovative solution that combines high performance, energy efficiency and environmental friendly solution. Thanks to its advanced configuration and distinctive features, the equipment meets the most challenging needs in the sector guaranteeing an optimal asphalt recovery and an high-level operational efficiency. Centauro model versatility allows you to manage materials that are difficult to handle in the meantime ensuring a constant productivity even in non-optimal working conditions. What makes the Centauro model crushing equipment really special is its patented technology capable of exploiting that harnesses shear effort to crush materials. This technology can reduces energy consumption, operating costs and environmental impact, without compromising the crushing process efficiency. Centauro XL 150.69 APR Pros The Centauro XL 150.69 APR, as mentioned above, combines two shredders, a magnetic iron separator and a vibrating screen in a single solution. The equipment come with various automatic programs for shredding different materials and is also able to treat wet materials, recovering 100% of the asphalt. The Centauro XL 150.69 APR is equipped with a Caterpillar C9. 3 endothermic diesel engine that complies with the latest pollution regulations (being Stage V licensed), offering high performance in terms of consumption and productivity. In order to reduce its environmental impact, the plant is equipped with a single generator set powering the electrical components allowing a 70% reduction in fuel consumption compared to traditional hydraulic machines while maintaining an hourly production constant level. This feature makes the CAMS model unique on the market compared to its competitors. Bitumen and aggregates recovery The bitumen and aggregate recovery system of the Centauro XL 150.69 APR is a new concept compared to traditional machines: the shredder works at low RPM and therefore breaks up the material without altering its granulometric curve. The equipment disintegrates the material without shattering as it happens with hammer machines, thus allowing total recovery of bitumen and aggregate. Advantages of materials disintegration Material disintegration, compared to crushing, provide the plus of optimal separation of bitumen from the aggregate, in favor of a better classification of the finished product and a 100% recovery of the material. A quickly spinning shredder does not allow you to recover everything because a large part of the volume is occupied by the filler, which among other things bring the risks of clogging the filter and drums. The Centauro XL 150 APR technology on the other hand turning slowly produces clean material and does not damage the system with less energy consuming. Therefore, the output material is of good quality and with a much higher percentage of bitumen recovered compared to traditional systems. Furthermore, operational well-being should also be highlighted: this is a technology that makes no noise, no dust, and no vibrations, but which above all is electric so it maintains low emissions and consumption Easy transport Another feature of the Centauro XL 150.69 APR equipment not to be underestimated is related to its logistic and handling since it is a mobile machine on tracks and in the shapes permitted by the road code. As a consequence its transport on a trailer and its handling on the construction site are easy. Another not insignificant aspect is its modularity that allow you to decide whether to insert the secondary shredder according to your needs.

-

Lifting Appliances

Magni RTH 10.37: the telehandler of records

Magni renews for 2024 its high-capacity rotary telehandler range. Especially the RTH 10.37: the world's current tallest rotary telehandler Magni during 2023 expanded and improved its range of high-capacity RTH rotary telehandlers. This range can now count in particular on the 10.37 model, which to date represents both the tallest model in the world and the one with the highest lifting capacity. An impressive 13 tons for the rotary telehandlers category. The new models available from mid-year were: 5.18, 6.22, 6.26, 6.31, 8.26 and 10.37. The new RTH 10.37 The RTH 10.37 is a rotary telescopic handler ideal for both construction sites and rental fleets. It is compatible with a wide range of attachments thanks also to the RFID system that provides automatic recognition and creation of the relevant load tables. This compact and multifunctional telescopic handler can meet a wide variety of applications in construction and industry. It features pivoting outriggers with a large contact surface area and a load monitoring system to protect against the risk of overloading and offers three steering modes. Features of the new RTH 10.37 include the new Load Live Diagrams (LLD) on-board software, which allows the load diagram to be displayed in three different ways and several state-of-the-art systems, including the easy access system, which provides easy access to the cab. Brand-new cabin For 2024 Magni has launches a new line of cabs, which basically have been moved forward from the turret to improve visibility. The seat is now closer to the forks and there is more glass area. A second access on the opposite side of the chassis has also been added. The new cab is equipped with the easy access system, a Magni patent, which allows the rotation of the machine to be locked to make it easier to enter the cab. The door opens 180 degrees and can be easily unlocked from the ground. The interior has been totally revised: all coverings have been injection moulded which results in high precision details and finishings. When the door opens the courtesy lights located under the armrests of the seats and under the push-button panel switsches on immediately. Total visibility A better visibility is made possible by the tapered steering column and the wiper motor housed in the lower part of it. The vents are always open and provide a constant flow of air to defrost/mist or clean windows. The operator is immediately alerted with indicator lights when a control cannot be performed for safety reasons. In the upper part of the cabin are two technical compartments holding most of the electrical units, fuses and diagnostic sockets, in order to simplify extraordinary and routine vehicle maintenance. The remote control has been housed in a dedicated case to protect it from dirt, wear and tear and accidents. The seat has also been renewed with two armrests with courtesy lights included. A standard rear camera has also been implemented on the entire RTH range to monitor the rear manoeuvring area. Images can be viewed on the touch screen (available as an option in the TH and HTH ranges). Software has been unified for the entire range in order to improve diagnostics and speed up control and update operations. The load diagram screen is available in three versions: standard view; dynamic real-time view, in which you see only the area where you can move with the load safely; and dynamic view from above. Ergonomically designed, the left joystick is available in three variants to meet every operator need. The right RTH/HTH and TH models’ joystick has two versions for complete customization of movements. The dashboard has been adapted and unified for all Magni ranges. A subnetwork to the Can Bus was also created to manage the analog buttons on the on-board console. Expanded TH range Another news from Magni for 2023-2024 is the expansion of the range with the 4.5.15 / 4.5.15 P and 4.5.19 / 4.5.19 P models. The new models feature a new chassis for maximum visibility and easier cab access. Standard all-wheel drive ensures maximum grip on all types of terrain. The hydrostatic transmission ensures optimal off-road performance. Both models will be available in two different engine configurations: the Deutz TCD 3.6 Stage V (with DPF) - 55 kW for the TH 4.5.15 and TH 4.5.19 models; the Deutz TCD 3.6 Stage V (with DPF + AdBlue) - 74.4 kW for the TH 4.5.15 P and TH 4.5.19 P models. The new models have compact dimensions making them ideal for working in tight spaces ensuring maximum manoeuvrability in any location. The pivoting outriggers remain perfectly contoured when closed and do not affect ground clearance, but they form a very compact stabilization area when extended, providing impressive stability and lifting capacity. Both models are equipped with a +/- 8° rubber-mounted levelling system that allows the operator to adjust the machine's levelling and have the full load chart for all operations, even with ground inclinations that would normally compromise lifting performance. New security system Magni has also introduced for the TH 4.5.15 P and TH 4.5.19 P an additional safety device for levelling. If the operator tries to manually correct the machine's tilt on uneven terrain, the system detects the machine's inclination and allows compensation only in the correct direction preventing any movement that could make the situation worse.

-

Components

MOBA Electronic A4U and myA4: the Cloud in the worksite

A4U and myA4 are the end-to-end solution, flexible for all OEMs in the Mobile Machinery Sector, which enables global, two-way communication from Mobile Machine to the Cloud A4U is the name of MOBA Electronic's flexible, end-to-end solution which has been designed for all OEMs in the mobile machinery sector for the lifting, road paving and earthmoving machinery sectors in general. A4U allows global, two-way communication from mobile machine to the Cloud. MOBA's A4U solution is based on a series of IoT services which, through the myA4U platform, allow OEMs to follow their customers with data management with benefits for the operational efficiency of the machines involved. The further advantage of A4U (which includes the related myA4U platform) is that of a product responding to the needs of 4.0 Industry, allowing access to all the tax advantages of the related national legislation. A4U: what it is specifically about A4U is the control unit, in slave-gateway mode, installed on the mobile machine, connected directly to the CANBUS line. Once the setup of telematic data to be monitored remotely is finished, quickly and easily, a two-way communication between the A4U device and the myA4U portal allows the data management. The software myA4 is an easily scalable Cloud infrastructure that manages all machine data in a secure manner and has powerful processing capabilities. It is an all-in-one telematic web portal dedicated to OEMs, their dealers, renters and end customers, which allows to implement the management of the mobile machine at a new level, using more in-depth analyzes of the vehicle , digital workflows, the possibility of updating machines remotely, thus applying the concept of Smart Mobile Machinery in a real way to any type of earthmoving machine. myA4: how it works The profiles of the Client Companies (OEMs) are created on the myA4U platform. Each of them can create on the other side the profile of their clients, who can access and use it in complete autonomy. For each user, access is guaranteed by user ID and password, from PC, tablet or smartphone, at any time. The myA4U platform is designed to be flexible, easily adaptable to the needs of the type of machine, which can be quickly programmed according to the needs of the manufacturer (OEMs), defining the data-setting that must be transferred from the machine to the Cloud. Thanks to the myA4U solution, you can take advantage of features that allow to range from simple remote data monitoring, to data logging of operating data, up to more advanced features such as predictive maintenance, or analysis of the aging of structures and some materials. The data flow in two directions The bidirectional data transfer of the A4U device allows real-time remote access to equipped Mobile Machines, as well as a wide range of IoT functionalities, such as remote updates of application software, or machine operating parameters, at extremely low costs. The necessary equipment on the vehicles On the mobile machine side, interfacing is guaranteed by the presence of 3 CAN-BUS ports, 1 Ethernet port, 1 USB port, 1 RS232 port, as well as a small I/O battery. The A4U was designed to be used in extreme environmental and working conditions. The robust boxing, with the electronics completely bathed in resin, allows to satisfy the IP67 standard and the high demands of all Offhighway applications, including extreme operating temperatures. The A4U features LTE connectivity capable of supporting the most important global frequencies, making regional variants or limitations obsolete. 4G connectivity is guaranteed by an embedded SIM-card which allows you to install the gateway ready for use, also eliminating roaming problems. The A4U is able to capture and track the positioning of the mobile vehicle thanks to a GPS interface to be connected externally, while it can also be optionally equipped with a Wi-Fi interface.The A4U device is supplied preconfigured and ready to use, in Plug and Use mode, without the need for additional settings, with internal status feedback and connectivity via LEDs on the container. The SLAVE-Gateway A4U control unit, on the other hand, is already equipped with SIM-Embedded for immediate installation and activation. Finally, the 4G and GPS antennas are incorporated in a single body.

-

Bauma

Interview with Hanane Rafya - Export Deparment at Sir Meccanica.

We're at Messe Munchen for bauma 2022 and we had the pleasure to make an interview with one of the main partner of ITALY@bauma. What indications emerged during the fair regarding challenges and opportunities for the Italian construction industry in the near future? How is Sir Meccanica preparing for these challenges? We've asked these questions and more to Hanane Rafya from the Export Department at SIR Meccanica. Sir Meccanica is a leading manufacturer of portable machine tools for grinding jobs such as reaming, welding and flange facing. The Italian company has presented a limited edition product at bauma 2022 to celebrate the company's 30th anniversary. Click here and discover more about SIR Meccanica. Visit SIR Meccanica

-

Demolition

Trevi Benne: the new FR18 crusher

Trevi Benne launches the new FR 18 which completes the range of rotating hydraulic crushers of the manufacturer from Noventa Vicentina Trevi Benne for 2023 focuses on a brand new crusher. This is the FR 18 rotating crusher, which completes the range of hydraulic equipment currently divided into 12 models.The structural characteristics of the new Trevi Benne crusher allow the operator to deal with all the demolition phases with a single piece of equipment. Precise and fast like a pliers thanks to the continuous hydraulic rotation, powerful and productive thanks to the jaws typical of a breaker. The new FR 18 is an equipment designed to be even more performing and durable against the typical stresses of the demolition phases. In fact, the new FR 18 has been redesigned in terms of shape and is now definetly more reliable. This new 1,890 kg model has several technical aspects to be mentioned: a double engine set as standard for the rotary unit, threaded pins with increased diameter, new regenerator valve. They are designed to offer a reliable solution in both primary and secondary demolition. The presence of the speed multiplier valve also makes it extremely fast in all operating phases. The structural changes The new structural features of the FR18 allow the operator to get a precise and fast tool like a pliers thanks to the continuous hydraulic rotation but at the same time powerful and productive thanks to the jaws typical of a breaker.The structure has been strengthened and the profile is even more aggressive while the rotation has been strengthened with a double engine option. A new HD interchangeable tooth system has been provided and the crushing area of the jaw and frame has been increased to promote penetration and productivity. Welded anti-wear inserts have also been applied to protect the structure and the jaws have been redesigned which now have a profile designed to facilitate cleaning of the material on the ground. The entire FR range The demolition range dedicated to concrete is available both in the standard version and in the pressure multiplier version. The FR Premium range, in particular, offers sector specialists four models that increase efficiency and productivity on site. With operating weights from 2,130 to 4,000 kg they are suitable for coupling with excavators from 15 to 53 tonnes. The Impact Booster valve The Impact Booster valve, which characterizes the Premium lines of demolition equipment from the Veneto-based manufacturer, has also been installed on the FR18. It allows you to increase the operating pressure to 750 bar, thanks to a system that exploits the overpressure generated during use. The advantages in terms of efficiency are first of all a fuel consumption reduced by up to 20% and an opening and closing cycle that takes place in just 4 seconds. This is due to the small diameter of the drive cylinder. Performance, in terms of breaking force, increases by 25% compared to the standard versions. A heavy duty machine The FR Premium series has a completely revised structure according to the greater stresses induced by the increase in operating pressure. The increased performance required a frame and brake shoe with greater strength at the points of greatest stress. The rear of the chassis has been screened to prevent waste material from entering during demolition work. The operational performance of the FR Premium varies between 90 tons of breaking force at the tip of the FR18P model up to 150 tons of the FR38P. We reach 105 and 120 tons with the FR23P and the FR28P.

-

Systems & Services

Construction machine thefts and how to prevent them.