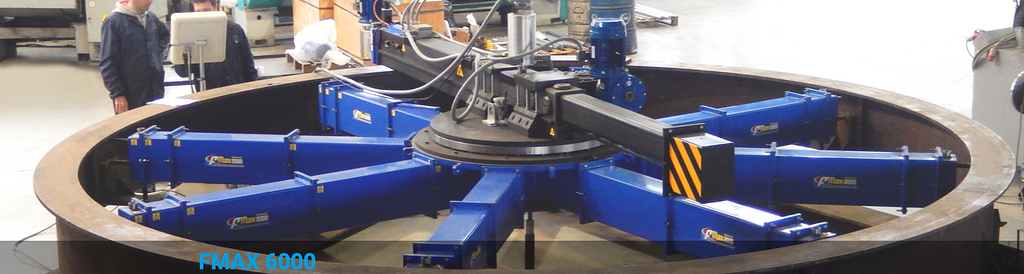

New-concept machines entirely controlled by an electronic controller, capable of performing the most diverse machining jobs on the faces of large cylindrical tubing, achieving unprecedented finish and accuracy results. F-Max overcomes all technical/structural and vibration-related issues thanks to the simplicity with which it can be quickly installed on site; the lightweight for easy handling and to the multi-functionality.

Perfect inertia balancing permits operation in any position: horizontal, vertical and inclined. Its unique structure compensates for radial and axial stress and tilting moment, minimizing harmful vibration. F-Max may also be used as a precision drilling/tapping machine. Once the diameter and number of holes have been set, the electronic controller automatically determines all drilling positions like an electronic indexing head.

Milling Contouring Calibrated drilling on circular series Tapping on circular series Creation of circular pockets Circular mig welding Circular oxygen cutting Being designed to guarantee the maximum reliability and ergonomics, the Fmax Controller combines practicality and design in one solution. The control panel can be adapted according to the height and the inclination required by the operator granting the maximum comfort for maneuverability and legibility.

There are 4 controlling areas, one for each movement of the machine:

[S] – milling rotation. [R] – machine rotation. [X] – radial feed. [Z] – axial feed.

For each movement, it is possible to set the direction and speed independently; All the speeds, both translation [mm/min] and rotation [rpm], are continuously monitored in an independent way. The translations are manageable through the “Fast Feed Switch”, and for each one, there is a STATUS display for the diagnostics of the functioning status. Each control area, is supplied with a ST.P led bar, thanks to which it is possible to verify the momentary working load. When the ST.P led bar flashes, it warns the operator that the machine is overloaded, giving the possibility to modify the cutting parameters properly. In the electronic divider/positioner version for circular series of holes, the controller is equipped with an additional alphanumeric LCD display, having 3 more switches and a signal lighting tower that can be bent to function as a led. By indicating the number of holes according to the diameter on which they need to be equally distributed, this optional accessory, positions the machine on the exact coordinates on which each hole will have to be placed; The alternate switching on of the 3 colors, along with the acoustic signals, continuously guides and updates the operators, who are far from the controller, on the working status in progress.